Abstract

The target of i-FLEXIS is the development of an innovative, reliable and low-cost integrated X-ray sensor system based on heterogeneous inorganic, organic and hybrid components.

It offers real time, direct X-ray detection, room temperature operation and a "designed for industrial production" approach, delivering operationally robust and environmentally friendly devices surpassing current state-of-the-art sensors thanks to brand new and highly needed new functionalities like conformability, flexibility, large active area coupled to low weight, low power consumption, portability, optical transparency, recyclability and/or sustainable disposability (zero waste, according to REACH directives).

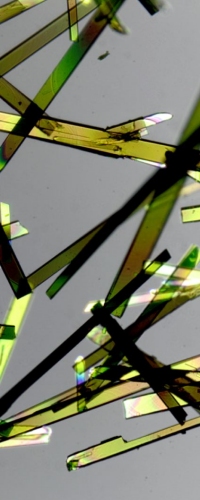

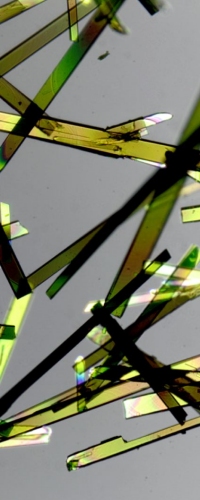

i-FLEXIS integrates three major novel concepts, recently demonstrated as a proof-of-principle operation at laboratory scale, allowing for totally new sensing systems: organic single crystals as the active, X-ray direct sensing material, high mobility thin film transistors based on nm-thin films of novel high mobility oxide materials operating at ultra-low voltages and flexible transparent electronics, all integrated onto low cost plastic substrates. These new concepts, will be developed and implemented using micro/nanotechnology and will be integrated into the final well beyond-the-state-of-the-art sensor system that will consist of multiple sensing units integrated as a 2D matrix and will be scaled up to 10cm x10cm with printing techniques compatible with industrial production.

The readout electronics for the whole system will be implemented by a on printed organic and oxide TFTs.

To validate the project outcome, the key-enabling technology of the i-FLEXIS system will be applied to two demonstrative contexts (test vehicles), to highlight its wide application potential:

1) health diagnostic radiation sensor for bone density analyses and to determine the dose on the exposed area;

2) Identification tags to monitor the airport X-ray screening history of luggage.