Objectives

The target of i‐FLEXIS is the development of an innovative, large‐area and low‐cost integrated Xray sensor system based on heterogeneous components, away from silicon technology or other similar covalent materials based devices/systems.

i‐FLEXIS offers real time, direct X‐ray detection direct conversion of X‐ray photons into an electrical

signal), room temperature operation and a "designed

for industrial production" approach, delivering

operationally reliable, robust and environmentally

friendly devices surpassing current state‐of‐the‐art

sensors thanks to brand new and highly needed new

functionalities:

- i. conformable and bendable: the materials employed in the fabrication of the nanoscale devices that are integrated in the large are

a radiation sensor system can be processed at very

low temperature (≤150 °C), allowing to realize the complete system on flexible substrates, such as plastics or paper.

a radiation sensor system can be processed at very

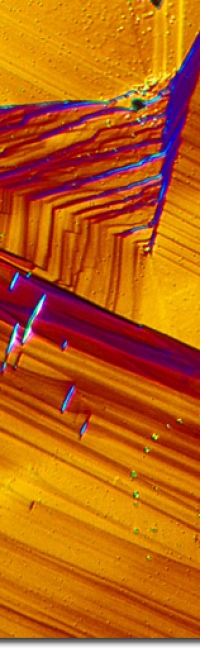

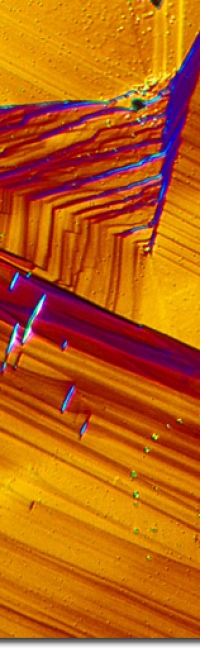

low temperature (≤150 °C), allowing to realize the complete system on flexible substrates, such as plastics or paper. - ii. optically transparent: the active materials used for the devices (organic single crystals and high mobility oxide thin film semiconductors) coupled to the use of plastic substrates and thin layers of printed metal interconnects grant a very low visible impact to the final complete system.

- iii. operation at ambient conditions: stable at room temperature, in air, under ambient light

- iv. low‐cost fabrication techniques: solution‐grown organic crystals, plastic substrates, low cost, high throughput printing processes (inkjet, screen‐printing), scalability to sheet‐to‐sheet allow to easily envisage affordable mass production processes.

- v. sustainability: low fabrication cost, low operating energy requirements, use of abundant raw materials and recyclable (zero waste, according to REACH directives), disposable if needed.

- vi. portable applications: thanks to the low requested power supply (operating bias voltage ≤5V), the light weight (10 gr for the 10 x 10 cm² demonstrator) and its conformable properties.

Scientific targets

- 1. develop organic single crystals (OSSC) grown from solution at low cost, chemically engineered to directly provide an electrical output signal when exposed to X‐ray radiation fields with energy ranging 10keV‐150keV and doses up to 104 Gy.

- 2. design and fabricate a photonic sensor unit that integrates the OSSC as the active X‐ray sensing element and appropriate amplification of its electrical output signal (that could vary from 0.01‐10μA).

- 3. design and integration of the whole i‐FLEXIS system, integrating the photonic sensor and the readout electronics into a 2D matrix that will act as a pixellated X‐ray sensing system. A fully printed organic CMOS platform will be used and proof of principle for an oxide TFT based low operating voltage (5V) CMOS one will be introduced. The fabrication process will be scaled to a 10x10 cm² prototype.